Introduction

PCBPit, short for Printed Circuit Board Pit, represents a significant advancement in electronics manufacturing and design. This technology has become a cornerstone in modern electronics, offering enhanced efficiency, customization, and integration capabilities—the intricacies of PCBPit, exploring its history, applications, advantages, challenges, and future trends.

History of PCBPit

Origins and Development

The origins of PCBPit can be traced back to the early developments in printed circuit board (PCB) technology. Over the years, PCBPit has evolved from simple circuit designs to highly complex, multilayered systems that support a wide range of applications.

Key Milestones in PCBPit Technology

Significant milestones include the introduction of surface mount technology (SMT), the development of flexible PCBs, and the advent of advanced manufacturing techniques such as additive manufacturing and 3D printing.

Core Components of PCBPit

Hardware Aspects

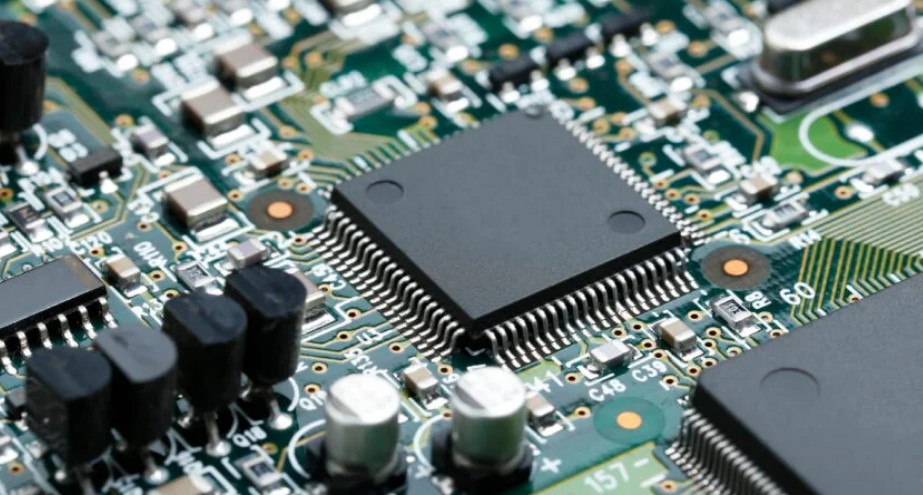

PCBPit comprises various hardware components, including the substrate, conductive pathways, and electronic components such as resistors, capacitors, and microcontrollers. These elements work together to form a functional circuit.

Software Integration

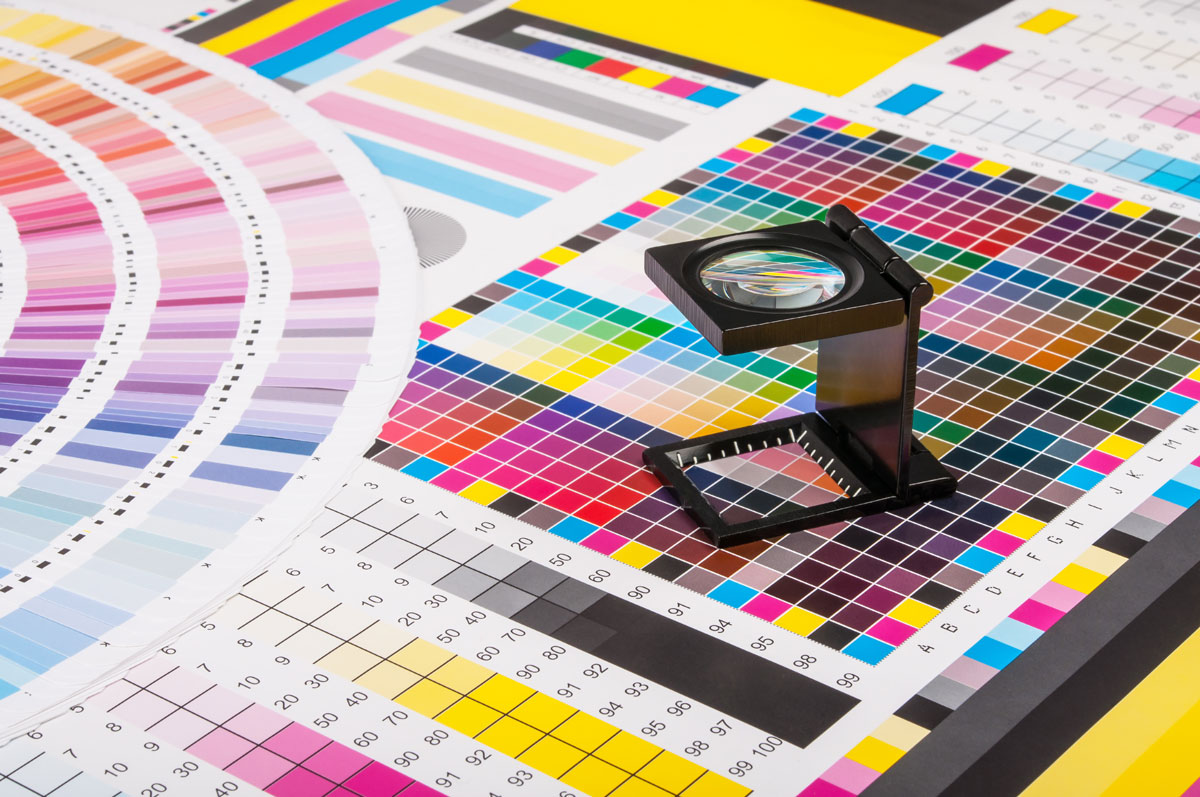

Modern PCBPit systems often incorporate software integration for design, simulation, and testing. This allows for more efficient development processes and improved performance metrics.

User Interface and Experience

The user interface of PCBPit design tools plays a crucial role in the usability and efficiency of the technology. Intuitive interfaces and user-friendly software contribute to better outcomes in PCB design and implementation.

Applications of PCBPit

In Consumer Electronics

PCBPit is widely used in consumer electronics, including smartphones, tablets, and wearable devices. Its ability to support complex circuits in compact spaces makes it ideal for modern gadgets.

In Industrial Automation

In industrial settings, PCBPit enables the automation of processes through the integration of sensors, controllers, and actuators. This leads to expanded efficiency and diminished operational costs.

In Medical Devices

Medical devices such as diagnostic equipment, implantable devices, and monitoring systems rely heavily on PCBPit for their functionality and reliability.

Advantages of Using PCBPit

Efficiency Improvements

PCBPit offers significant efficiency improvements over traditional PCB systems, including faster production times and lower energy consumption.

Cost-Effectiveness

The cost-effectiveness of PCBPit is another major advantage, particularly in large-scale manufacturing where economies of scale can be realized.

Customizability

One of the key benefits of PCBPit is its customizability. Designers can tailor PCBs to specific applications, ensuring optimal performance and functionality.

Challenges and Limitations

Technical Constraints

Despite its advantages, PCBPit faces technical constraints, such as limitations in material properties and challenges in achieving high levels of miniaturization.

Market Adoption Barriers

Market adoption of PCBPit can be hindered by factors such as high initial costs, resistance to change, and the need for specialized skills.

Regulatory and Compliance Issues

Compliance with regulatory standards is critical in industries like healthcare and aerospace. Navigating these requirements can be challenging for companies implementing PCBPit.

How to Implement PCBPit in Your Business

Assessing Business Needs

Before implementing PCBPit, it’s essential to assess your business needs to determine if this technology aligns with your goals.

Step-by-Step Implementation Guide

A step-by-step guide to implementing PCBPit includes selecting the right tools, designing the PCB layout, prototyping, and testing the final product.

Common Pitfalls to Avoid

Common pitfalls in PCBPit implementation include overlooking design considerations, underestimating costs, and failing to comply with industry standards.

Case Studies

Successful PCBPit Implementations

Case studies of successful PCBPit implementations highlight best practices and lessons learned from real-world applications.

Lessons Learned from Failures

Analyzing failed PCBPit projects can provide valuable insights into what to avoid and how to approach future implementations more effectively.

Expert Insights

Interviews with Industry Leaders

Industry leaders share their insights on the current state of PCBPit technology and its future direction.

Predictions from Experts

Experts predict that advancements in materials science and manufacturing processes will drive the next wave of innovation in PCBPit.

Future Trends in PCBPit Technology

Emerging Technologies

Emerging technologies such as flexible electronics, organic PCBs, and nanotechnology are set to revolutionize the PCBPit landscape.

Potential Impact on Various Industries

These advancements will have far-reaching impacts across various industries, from consumer electronics to automotive and healthcare.

Practical Tips for PCBPit Users

Best Practices for Maintenance

Regular maintenance is crucial for ensuring the longevity and reliability of PCBPit systems.

Troubleshooting Common Issues

Tips for troubleshooting common issues in PCBPit systems include checking connections, updating software, and conducting regular inspections.

Comparison with Other Technologies

PCBPit vs Traditional PCB Systems

Compared to traditional PCB systems, PCBPit offers superior performance, flexibility, and cost-effectiveness.

PCBPit vs Emerging Alternatives

Emerging alternatives to PCBPit, such as hybrid circuits and flexible electronics, offer different benefits and trade-offs.

Regulatory and Compliance Considerations

Understanding Compliance Requirements

Understanding and adhering to compliance requirements is essential for businesses using PCBPit in regulated industries.

Adapting to Changing Regulations

Staying ahead of regulatory changes is critical to maintaining compliance and avoiding costly fines or product recalls.

Tools and Resources for PCBPit

Recommended Software

A list of recommended software tools for PCBPit design and implementation, including both free and paid options.

Training and Certification Programs

Information on training and certification programs that can help professionals stay up-to-date with the latest PCBPit technologies.

Conclusion

PCBPit is a versatile and powerful technology that offers numerous advantages across various industries. However, it also presents challenges that need to be carefully managed. As PCBPit technology continues to evolve, staying informed and adapting to new developments will be crucial for businesses and professionals alike.